24k-30k-60k Service - isv valve

Here are links to the other parts of the servicing: 1. 60k service schedule

The idle stabiliser valve does exactly what you would think. By carefully bypassing air from the throttle body (according to temperature & engine speed) it helps maintain a stable idle. It does however get clogged up with dirt, oil, gunk and nasty black stuff on a fairly regular basis which can lead to a poor or wavering idle and the well known stalling when reversing sympton. Inside is a kind of barrel or butterfly switch which must be free to open and close, thereby modulating the flow of air and it's easy for this to be compromised by all the gunk. Routine cleaning is therefore a good idea but although it's on paper it's one of the very simplest jobs a 993 owner can perform, if you haven't tried it before then ensure that you read the small print because it can very quickly become one of the most frustrating.

On top of the manifold we have one ISV valve. At the back of it a rubber hose connects to it (with jubilee clip) and at the front a metal pipe that goes into a short length of rubber hose secured with another 2 jubilee clips..

You have 3 clips to undo here then. Chances are they may be pointing at more unhelpful angles than mine. Your best friend here is a dedicated flexible 6mm worm drive screwdriver. Second best a flexible extension on a ratchet or a couple of universal joints and some extensions. Loosen everything, unclip the electrical quick connect, pull out the metal pipe, ideally remove the short rubber hose (you don't want the jubilee clips scratching your manifold and getting in the way) and then push off the hose at the rear with some strong force using a pry bar, a big flat headed screwdriver or something similar. There's a good chance that any rubber will be stuck fast to the valve so it's a good idea to use a thin pick to prise up inbetween hose and metal and run it around the circumference loosening as you go.

Once the hoses/pipes are off, it's a good idea to push the rear hose as far back as possible. If you can tie it or get it out of the way semi permanently then do so. After that it leaves you more space to slide the ISV out. The valve runs through a cylindrical rubber gasket that sits in the fin on the manifold. Although mine wasn't too bad many people find that the valve is stuck fast to this piece of rubber as well. A very thin pick can help here and also spraying some oil or soapy water on the surface of the valve before you start pushing.

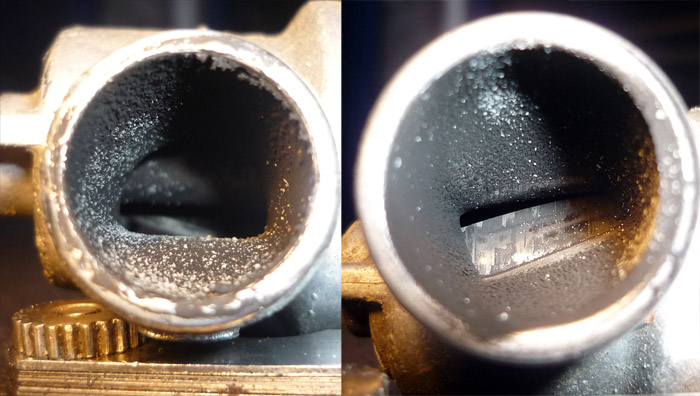

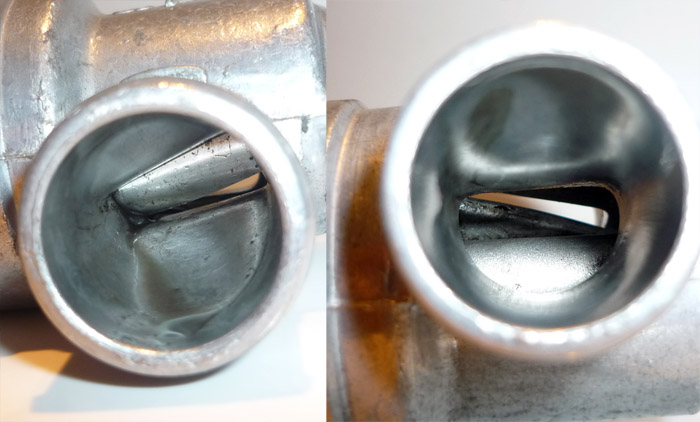

You can see the before and afters here. I soaked my ISV in white spirit overnight (but leaving the electrical connector and that end of the valve completely dry) and the next day I scrubbed the internals using brake cleaner and some pipe cleaners. If you give the thing a shake you should hear the valve freely opening and closing.

Now here's where it can quickly turn bad. The pitfall is to presume that this is any old easy job and just go in guns a blazing thinking that it only takes 20 seconds or so to push a piece of metal into a hole then hitch 2 hoses onto it. Wrong ! Take these precautions before you start and it will all be over a lot sooner: 1. coat the main body of the valve with a light mist of soapy water, WD40, 3 in 1 or something similarly slippery. 2. pull that metal pipe to the extreme right and cable tie it well out of the way 3. undo the clip on the rear hose even more and then push it downard along the length of hose away from the end 4. put a long screwdriver or something similar into the rear hose and then yank the screwdriver right and then backwards, forcing the hose out, back and down. I had my screwdriver jammed right behind the back of the manifold trumpets and as you can see in the picture it kept the rear hose completely out of the way. Ok, now the space is completely clear and you have some lubrication, guide the valve back through the rubber gasket (being careful not to dislodge it out of its bracket). Trust me, if the pipe and rear hose is still there obstructing your work area it becomes a very frustrating and painfully impossible process.

If need be, keep a screwdriver handy as you push, to bring the edges of the rubber mount back into line. If it pops out on the far side it's a real pain because you'll have to start all over again.

Once the ISV is back where it lives, release the rear hose and proceed to prise it onto the rear valve opening using a beefy screwdriver or something similar. It's a thick old bit of hose so you will need to be pretty brutal about it. Obviously guide the jubilee clip in place after this and tighten.

The metal pipe is a lot easier. Release then pull across and connect. Leave your worm drives in a friendly orientation for next time. Enjoy your new smoother and more stable idle !

|